EXPECTATIONS.

In terms of expectations for the course, I thought that there would be a lot more tool training and 3D printing involved. Instead, our time was split evenly between team prototyping and tool training. While I knew about the prototyping project, it was both less structured than I expected and more involved than I thought it was going to be. On one hand, we were given the guiding information and assignments to go about prototyping our ideas, but on the other hand, a lot of the initiative was left to our own self to start conducting outside research and interviews, start tool practice and learning, and start networking and testing our prototype. I had honestly expected the course to “hold our hands” a little bit more than they did, but I am very glad that it did not. In the end, I was able to learn more about the way that I tackle large projects without much guidance as well as learn more about design thinking and the prototyping process. Before, startups were a bit of a mystery to me, a buzzword many people use in business talks, but going through the prototyping process helped me truly understand what a startup does and how difficult that process is.

Another aspect I had not expected was how closely we worked with DRES. I had expected a course about digital making, especially a course housed within the Gies College of Business, to be more bottom line focused in their innovation themes, but the accessibility work and disabilities focus we had in class was a nice surprise. Having done some disabilities advocacy – albeit more on the mental health side rather than the physical disabilities side – before, being able to work in this field put me a little more at ease. It was incredible to see the real impact that our prototypes had on real people at the end of the course.

Group Interview at DRES with our mentors

To see a more in-depth break-down of what the first few weeks of class were like, read the following blog posts:

- Week 02 – If It’s Not Broke, Use It To Create Something New

- Week 03 – A (Polar) Vortex of Ideas

COMMUNITY + OPEN SOURCE RESOURCES.

It was really cool to be able to learn how to use a multitude of new programs within this class; the program I was most excited about learning was Autodesk’s Fusion 360. My brother took a 3D printing class our senior year of high school, and I was always fascinated by the projects he brought home to show our family. As a result, I was both anxiously anticipating and incredibly excited to work with 3D modelling for the first time during this seminar. Upon completing Lars Christensen’s Fusion 360 tutorial that we used to familiarize ourselves with the Fusion 360 program, I felt really accomplished and inspired to explore 3D modelling further.

Left: 3D printed phone holder, Right, from top to bottom: Fusion 360 file for phone holder, 3D printed box from Lars Christensen’s tutorial, 3D printing in process of Solestice logo

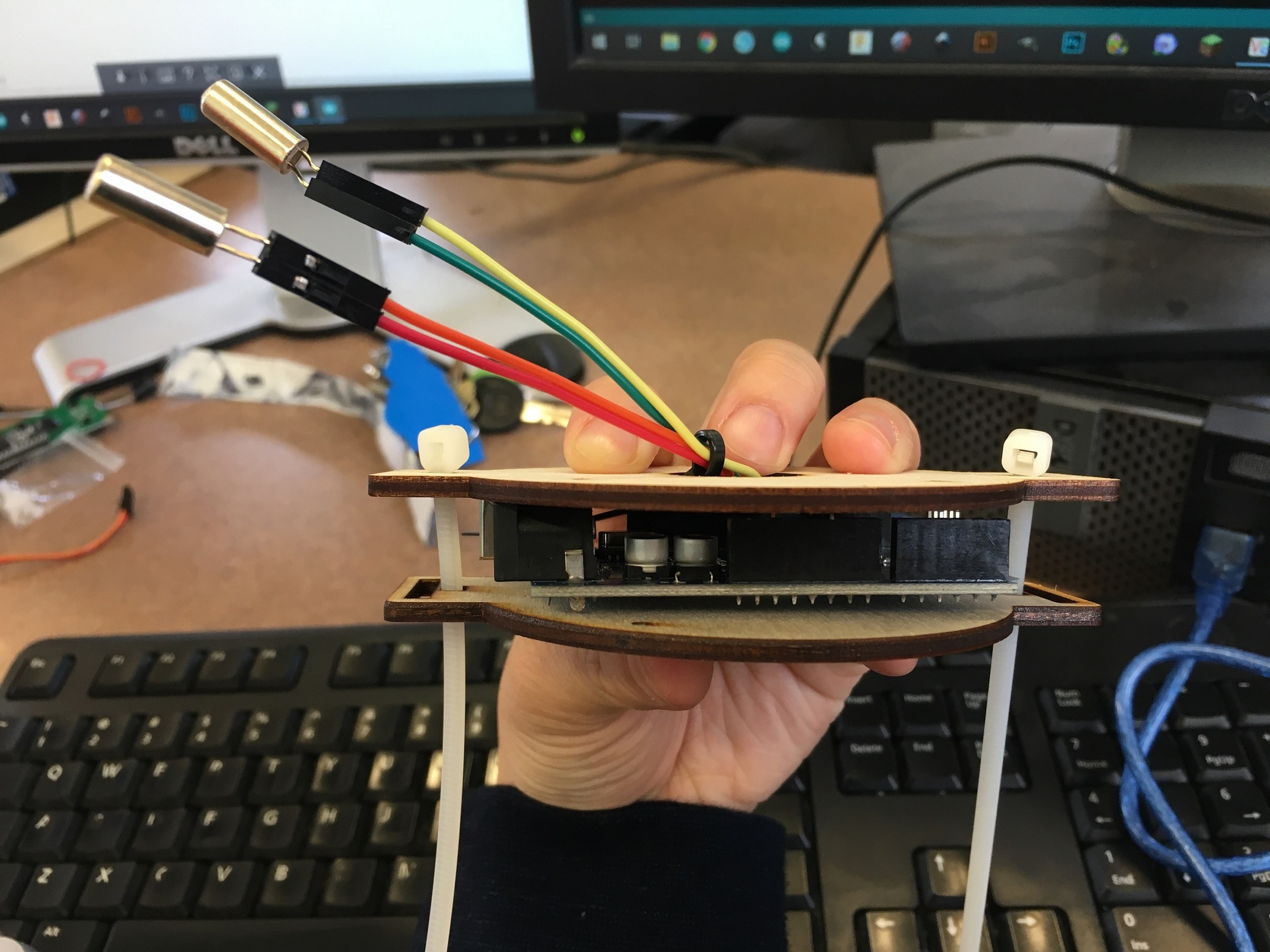

It was around the completion of our introduction to Fusion 360 that we were introduced to a community resource on campus: the Champaign-Urbana Community Fab Lab. For such a compact space, the amount of resources available there was incredible! I was so surprised that we had so many resources available to us as members of the Champaign-Urbana community, and yet, not many people knew of these resources. One of my goals after this class is definitely to let more people know about the plethora of resources we have available to us here in CU. During our three weeks at the CU Fab Lab, we completed a culmination project which taught us how to use Inkscape, an open source vector program similar to Adobe Photoshop or Illustrator, to create laser engraving files; create code and build Arduino programs and other electrical configurations; and use a sewing machine on various types of textiles. Overall, it was a really cool experience that allowed me to familiarize myself with new tools and gain new ideas on what types of innovation could be used to help me create my prototype.

Upper row, from left to right: Sewn watch strap, laser cut & engraved watch face, in-progress watch assembling, Arduino electrical component; Lower row, from left to right: Arduino code, finished exercise watch

For more detail on what the tool training experience was like for me, feel free to reference the following blog posts:

- Week 06 – A Fusion of Knowledge

- Week 07 – New Resources: A Fabulous Lab

- Week 08 – Copious Continued Concepts

- Week 09 – Watching It All Come Together

PROTOTYPING.

As part of the prototyping process, we went through many different concepts related to design thinking. First, we learned about human centered design and empathetic design, which really appealed to me. Before, I thought that innovation and prototyping design was only for the random moments of inspiration where someone looks at a problem and is struck by the inspiration to find a solution to it in order to make money. However, we were taught that wording is another important aspect of designing and that we should think of our prototypes not as “solutions to problems” but “ideas for to fill an opportunity,” something that we can use to help people with. We also learned about diverging during the brainstorming process and then converging back upon a decided path to take a prototype idea. Through this process, I was confronted with my indecisive nature. Although I had subconsciously known this, I had not realized why I was so indecisive. Yet, during the prototyping process, I realized that I was indecisive because I feared the failure of arriving at the wrong answer. I disliked choosing a path, preferring inaction over actively choosing wrong. Taking this course has really helped me realize that about myself, and I now try to challenge myself in my daily living to make quicker decisions, to choose a path rather than being crippled into inaction. I am learning to trust my instincts and gut feelings a little more than I did before.

One example of this was the iterations that lead to the drastic changed between our (Team Solestice’s) low fidelity prototype, our Make-a-thon prototype, and our post-testing prototype. In the first prototype, we were thinking of using metal spikes as a source of traction, and we committed to the idea. However, upon further research, before we even got to the Make-a-thon event, we realized that it was not feasible, that it would be even more of a problem for a user to have to take the tread off and put it back on every time they switched between walking outdoors to indoors and vice versa. And here we thought we had the correct idea. Yet, after we tested our prototype with a prosthetic leg user, post-Make-a-thon, we realized once again an opportunity for change. We realized that the tread was too heavy and the Velcro too visible. So, we switched gears once again to look at being able to apply the tread directly to a shoe. So, it was through this course, our prototyping project specifically, that I understood an opportunity for myself to learn to face failure head on, to learn to be okay with the fear of failure, and to keep working, regardless.

Left: Post-Testing Prototype (3rd), Upper Right, Low Fidelity Prototype (1st), Lower Right: Make-a-thon Prototype (2nd)

For more details about the preparation I undertook with my team for the Make-a-thon event, take a look at the following blog posts:

- Week 04 – Progress Doesn’t Always Mean Walking Forward

- Week 05 – Two Roads Diverged, And I Made Peace With The Idea Of Not Trying Both

- Week 10 – Preparation Is Key

- Week 11 – All Final Checks Completed & Anticipation

This course has taught me so much, not only about the different innovation tools available in the market right now, but also about myself. I have grown not just in marketable skills, but also as a person, and for that, I am incredibly thankful that I took a chance, braced myself for failure, and applied to be a part of this course.

Salutations! I’m a sophomore studying accountancy who likes to create some art on the side (yes, I’m one of those photographer/poet/all around artist people). My passion is in advocating for equity, and I probably spend a little too much time on Hulu.

I am a part of Team Solestice with Trevor Sibby and Emma Bradford.

You must be logged in to post a comment.