This Wednesday, we participated in a workshop from Autodesk representatives on Fusion 360, an integrated CAD software. We were tasked with creating a phone holder. The representative leading the workshop walked us through the steps to design the phone holder. We are going to print them in the MakerLab later this week. I love this course because we are able to design and create things that we (or others) can actually use. You can see the phone holder I designed here.

In addition to designing the basic holder, we also had the opportunity to customize it. We could choose a material, paint colors, add decals, etc. This was my first time utilizing any CAD software, and I really enjoyed it. I thought the Fusion interface was very simple and intuitive. However, I have heard that this is not the case with other CAD softwares. I would love to learn different softwares and see how they differ form each other.

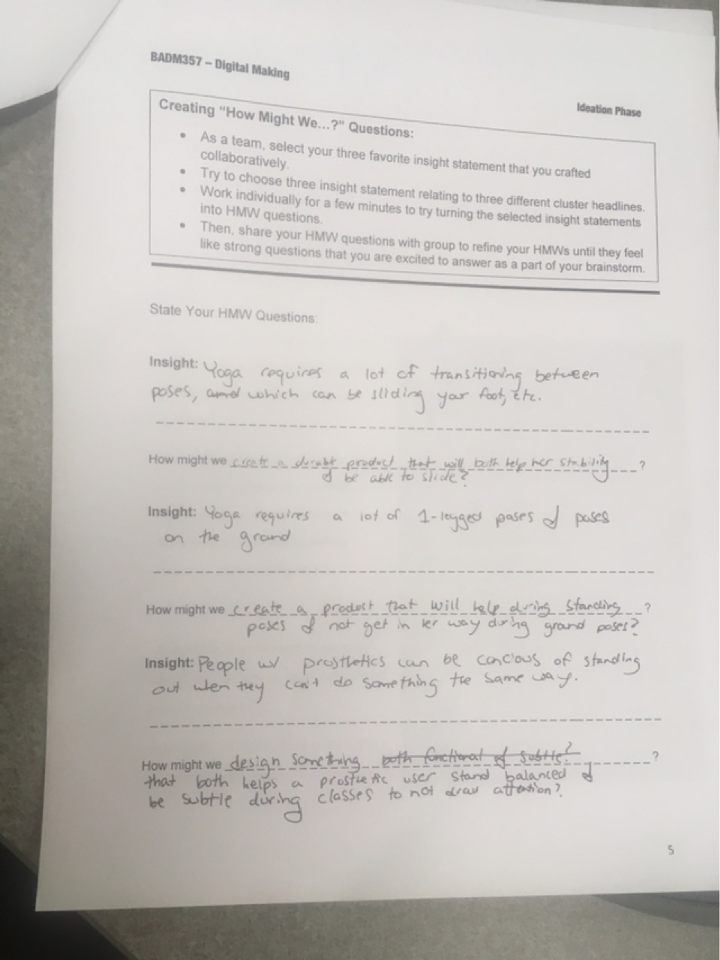

After the workshop, we had about 45 minutes to work with our teams to create “How Might We” statements. We used the post-it notes from last class to help us write them. My team narrowed our work down to 3 “How Might We” statements. These statements are an essential part of the Ideation phase of the design process, so we are testing if our idea to create a tread for prosthetic users will work. This activity challenged us to not be too broad nor too specific. We found it difficult to find a balance. I am looking forward to the next few weeks in the Fab Lab to continue our project!

Hi there! I am a Senior studying Marketing and Information Systems/Information Technology. I chose to take this course in order to expand my creative and design thinking skills that I can apply to my future career. I am grateful that we are provided the opportunity to take this course as Business majors.

You must be logged in to post a comment.