THE BIRTH OF SOLESTICE.

Almost everyone has, at one point in their lives, experienced the pain of slipping on black ice. This could be a story that your friends constantly make fun of you for, or a silent embarrassment you keep to yourself (and your neighbors who saw the whole thing). Slipping on black ice is definitely something that conjures a vivid image in everyone’s mind, and it was for this reason that our team felt such a connection with Jenna when we first interviewed her. The first time we met our mentor, Jenna Fesemyer, was during a large group interview our class conducted at the Disabilities Resources & Education Services (DRES) building. Our entire class was present to hear Adam, Arielle, Jenna, Ron, and Ryan talk about their frustrations. Jenna shared with us the story of a time where she slipped on ice immediately upon exiting her car and lamented the fact that she could not even wear boots for more traction in situations like these. We found out that the boots heavy weight prevented Jenna and other prosthetic users from wearing them as their residual limbs are not strong enough to carry too much weight. During our team discussion the following week, we decided to try to find a way for Jenna to increase traction without adding to much weight, and Project Solestice was born. Solestice’s goal is to create an attachable shoe tread that can be used to travel in a variety of rough terrains, with our first focus being on icy terrains.

A RESEARCH OPPORTUNITY.

Throughout class, we worked on different parts of the prototyping process, conducting interviews, researching different materials and methods, and defining the challenges and opportunities that inspired us. Solestice identified four opportunities: 1) prosthetic users cannot wear heavy-weighted shoes (like boots), so we will make an attachable tread that is optimized to be lightweight; 2) prosthetic users often fail to shift their full weight on their prosthetic leg, so we will use arduinos to create force feedback; 3) prosthetic users may have difficulty putting shoes on, so we will use elastic and design an easy to use mechanism; and 4) prosthetic users prefer an aesthetically pleasing design, so we will use lightweight, translucent material to make the tread less conspicuous. With the four identified opportunities, we took to the time to interview our mentor who is a prosthetic leg user, Jenna Fesemyer; a materials science professor, Matthew Goodman; and a professor who is also a shoe cobbler, Salman Raheel. Through this process, we found out that thermoplastic material is both lightweight and has enough traction to be effective. We also brainstormed many ways to attach the tread onto the shoe. At first, we believed that having spikes on the tread would help the most and made a low fidelity prototype based on it, but we ran into a problem when we realized that the user may have to take the tread off when walking indoors. The stage was set, and all we had to do was wait for the Make-a-thon event to start creating our very first functional prototype.

MAKING IT OUR OWN THING.

During the Make-a-thon, the work we did on the prototype could be broken down into three sections: Arduino, molding, and attaching.

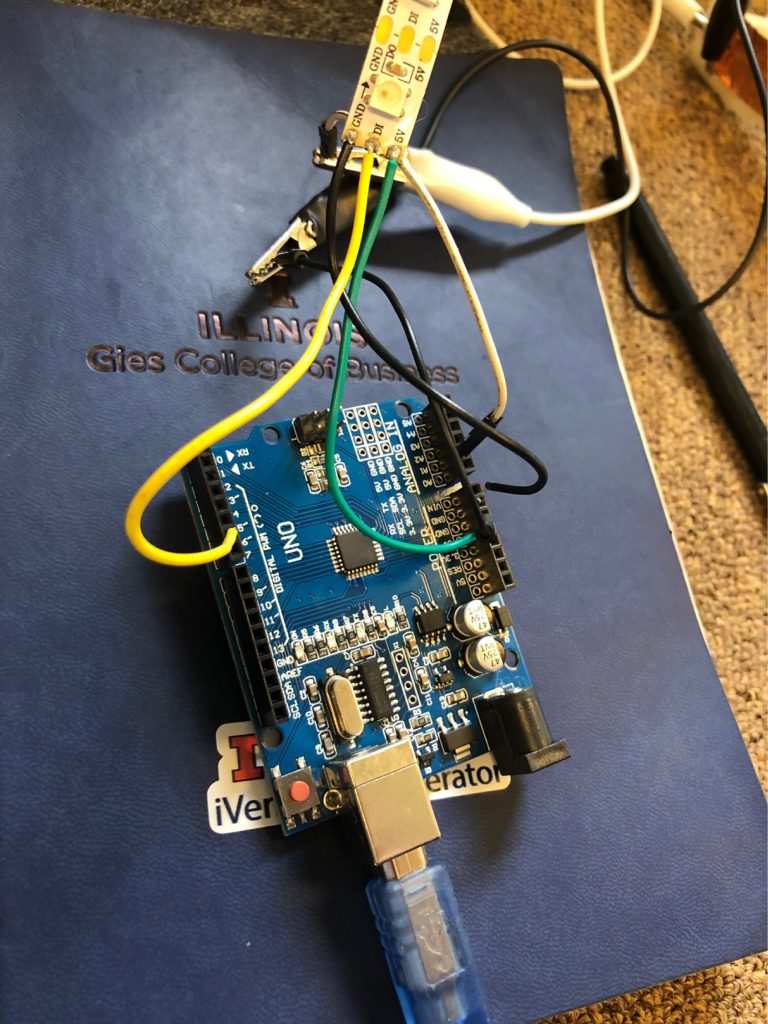

Arduino

For the Arduino portion of the prototype, we coded an Arduino Uno to illuminate LED lights when a certain amount of pressure is put on the tread; in other words, we created a basic Arduino based pressure sensor. To create the pressure sensor, we sandwiched a piece of foam with two pieces of copper. Ideally, we wanted for there to be three lights, each indicating where the user is putting pressure on the tread. This would enable the user to ensure they are putting enough weight on their prosthetic to maximize stability. The data collected from the tread could also eventually be collected and viewable in an app.

Molding

Using a molding compound and a cheap shoe we bought, we created a mold of a shoe outsole. During this process, we coated the shoe in baby powder and mixed the molding compound to a viscosity similar to pancake mix. We held the shoe down until the mold dried. Following, we used a hot glue gun to fill in the mold with thermoplastic material. After the mold was completely filled, we used a heat gun to smooth the top of the sole, making sure the edges were slightly taller than the inside of the sole. The thermoplastic material we used was similar to silicone and, per our research, is a material that creates enough friction to prevent falling on ice. Ideally, given more time, we want to be able to create the tread design ourselves with the information that we learned from Prof. Goodman on which type of tread design would be most effective for black ice. However, due to the time constraints of the weekend event, we made do with created a mold from the materials on hand.

Attaching

Due to time constraints, we attached the tread via Velcro. While we are not completely satisfied with this method, we were constrained by our budget, time, and materials. Ideally, we would like to use a clear, elastic material to follow the aesthetic we have already created. We will expand upon this more when we talk about testing, however, we are definitely aware that one of our biggest opportunities for further improvement is to research better, more aesthetically pleasing attachment methods. We want to find an attachment method and material that is easier for users to put on than Velcro. One way to possibly do that is to have less straps than we currently do with elastic material so that the Velcro mechanism is not too difficult a barrier.

First Prototype

Our first prototype was created from thermoplastic material and attached via three Velcro straps. In the back, we attached an Arduino which enables force feedback. This gives the user the opportunity to analyze where they are applying the most pressure and adjust accordingly. The tread weighs about 1.198 lb with a sneaker (0.598 lb individually), compared to the about 2 lb weight of a regular snow boot.

TESTING OUR METTLE.

Following the Make-a-thon event, we were able to test our prototype on three users: Jenna Fesemyer, our mentor and a prosthetic leg user; Jennifer Clifton, our Make-a-thon teammate and a person with brittle bone disease; and Kim Harden, an elder. While not all our testers were prosthetic leg users, they were all analogous users who would have a use for a tread like this. The feedback that we received was that while the tread itself did its job, the straps were difficult to put on, and the Arduino should probably used as a diagnostic instead of a daily part of the tread. While the tread had incredible “grippy”-ness, we along with most of our testers, felt that it was still a little bit too thick, and that during production, there is an opportunity that we need to identify where we can thin out the tread and make it even lighter. Furthermore, during testing, Jenna told us that she felt that because of the strap and how difficult that is to put on, the tread is not something she felt could be used every day. So, just like an umbrella, Solestice’s tread has a problem where if the user forgets to bring the tread out or wear it during icier days, it will not be of use. Some ways that we have thought of to try to improve this problem is to make either make the attachment mechanism easier or find some way to adhere the tread directly onto the shoe. Finally, Jenna thought the tread aesthetic looked very cool, and Kim thought it made her feel younger.

THE FUTURE IN OUR PALMS.

As mentioned before, there are several ways in which we would like to improve the prototype of Solestice treads.

Researching Even More

There are many topics that we have to do more research on. First, we want to confirm that the thermoplastic material we used is the material that can give the best traction. Next, we want to do even more research to create our own design to optimize the tread for black ice. We know from our interview with Prof. Goodman that a tread with a larger amount of surface area would be the best for black ice, so ideally, we would design something similar to the tread pattern of a winter tire. Furthermore, another idea that we want to look into is either adapting the tread or finding a material to make the tread shock absorbing in order to decrease the weight of the shoe for prosthetic leg users. Finally, we will be researching into whether it is possible to incorporate some type of cushioning for further comfort in the tread attachment without having to sacrifice the weight of the tread.

Business in the Long-Run

If we can raise enough support for Solestice treads, we feel one of our best options would be to partner with a shoe company. With this partnership, we can engineer a method of attaching the tread directly onto the shoe so that users of the tread can always have the tread on. Alternatively, more information from a partnership with a shoe company could give us data that allows us to create an easier, less complicated attachment contraption. Furthermore, we would gain more information on shoe designs in order to optimize our tread design. Partnering with a shoe company would also give us access to mass production machines, allowing us to create molds more efficiently, better control the thickness of the tread (thus making it thinner and lighter), and customize the tread aesthetics (offering more colors and aesthetic designs).

Additionally, the Arduino portion of the tread, once shrunk to be more compact, can become a separate product marketed towards physical therapists who help prosthetic leg users, the elderly, anyone else that has unstable footing, and even athletes. Through this, we can track data on where people put pressure on their feet and understand more on how that affects posture and other health areas. Eventually, an app tracking this information can be created and the data analyzed to help prosthetic leg users better trust their leg, the elderly understand how to stabilize their footing, and athletes where to put pressure when running or participating in other activities to achieve the best result. Said data could be sold to sports coaches, medical professionals, and other researchers. This data can also help people with lesser problems, such as duck feet.

To see our final presentation on Project Solestice, click on the following link.

To see our Instructable (detailed instructions on how to create our prototype), click on the following link.

This post was co-authored by AJ Poe , Emma Bradford , and Trevor Sibby.

Salutations! I’m a sophomore studying accountancy who likes to create some art on the side (yes, I’m one of those photographer/poet/all around artist people). My passion is in advocating for equity, and I probably spend a little too much time on Hulu.

I am a part of Team Solestice with Trevor Sibby and Emma Bradford.

Hi Team Solestice – really awesome reflection! I thought your final project was very cool and the arduino addition during the make-a-thon was very unique. I think it would be an incredible thing to be able to take data from testing the sole and then designing the sole customized around the user to optimize their walking. What a great semester! I think this is definitely an awesome topic overall and you guys did a great job of incorporating lots of different elements in your design – great work!

What is cbd?